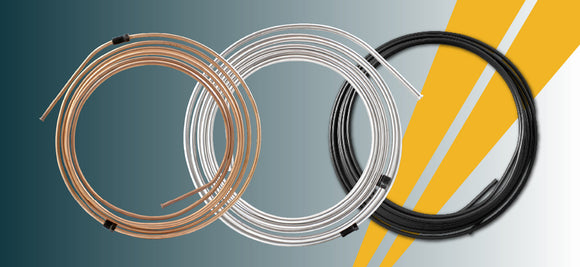

Brake Line Tubing: Material & Coating

The Role of Brake Line Tubing: Why Material and Coating Matter

When it comes to vehicle safety, your braking system is one of the most critical components—and at the heart of that system are the brake lines. These lines carry pressurized brake fluid from the master cylinder to each wheel, allowing your brakes to engage precisely when needed. But not all brake lines are created equal. The material and coating of your brake line tubing can significantly impact your vehicle’s performance, longevity, and reliability.

At 4LifetimeLines, we specialize in providing premium-quality brake lines engineered for professionals and DIYers alike. In this post, we'll break down the science behind brake line tubing and why choosing the right material matters more than you might think.

The Science Behind Brake Line Materials

Brake lines must be strong enough to handle thousands of pounds of hydraulic pressure, while also resisting corrosion, flex fatigue, and harsh environmental conditions. Here's how the most common materials compare:

Steel with PVF Coating

PVF (Polyvinyl Fluoride) is a plastic coating applied over traditional steel brake lines.

Pros:

- Affordable and widely used by OEMs

- Good corrosion resistance (better than bare steel)

- Paintable and easy to work with

Cons:

- Still susceptible to rust over time, especially in salted-road environments

- Not as easy to bend as other materials

Best for: Factory-style replacements and budget-conscious repairs

Shop our PVF-Coated Brake Lines

Stainless Steel Brake Lines

Stainless steel tubing provides superior corrosion resistance and strength.

Pros:

- Extremely durable

- Resists rust and pitting, even in harsh climates

- Great for performance or long-term reliability

Cons:

- Stiffer and harder to flare or bend (requires proper tools)

- More expensive than coated steel or copper-nickel

Best for: Performance builds, off-road use, and long-term reliability

Check out our Stainless Steel Lines

Copper-Nickel Brake Lines

This hybrid material combines the corrosion resistance of copper and nickel with the strength of steel.

Pros:

- Easiest material to bend and flare

- Superior corrosion resistance—does not rust

- DOT approved and widely used by mechanics

Cons:

- Slightly more expensive than PVF-coated steel

- Not quite as strong as stainless in extreme conditions

Best for: DIY projects, long-term repairs, and vehicles in high-corrosion environments

Explore our Copper-Nickel Kits

Choosing the Right Brake Line for Your Build

Whether you're restoring a classic, building a custom ride, or just replacing a rusty line, choosing the right brake line material matters:

- Need an easy-to-install option? Go with Nickel Copper

- Looking for a high-performance upgrade? Choose Stainless Steel.

- Want a budget-friendly, OEM-style repair? Opt for PVF-Coated Steel.

Upgrade with Confidence at 4LifetimeLines

At 4LifetimeLines.com, we offer pre-flared lines, coil tubing, fittings, tools, and complete brake line replacement kits—all designed with durability, ease of use, and quality in mind.

Browse our full selection of brake line materials and kits today → Shop Brake Line Products

Final Thoughts

Your brake lines are more than just tubes—they’re your first line of defense in stopping power. Choosing the right material and coating can be the difference between a brake system that lasts and one that fails when you need it most. Don’t compromise on safety—invest in quality components you can trust.